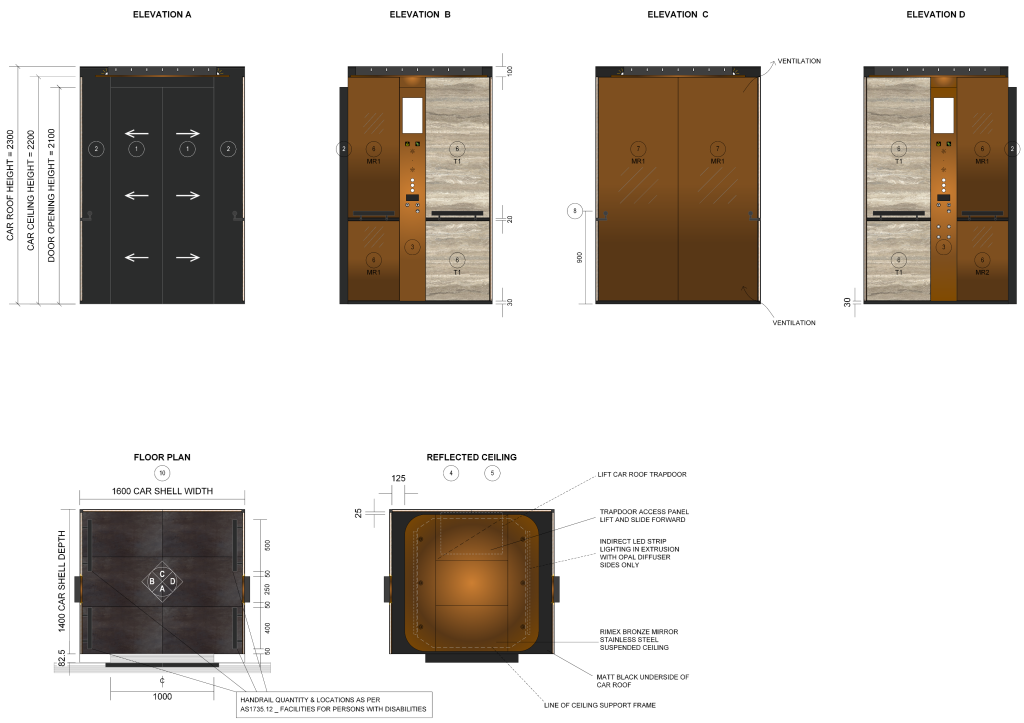

Manufacturing & Installation

Dual’s team of skilled craftsmen will personally measure, manufacture and install your Lift Car Interior, guaranteeing a professional personalized experience and meeting Australian Standards and Disability Compliance

Complete Solutions

Dual offers a Full Package Solution incorporating all aspects of Lift Production and Installation. Having competitive and reliable local WA suppliers along with a wealth of Interstate and International partners, we are able to source almost any part required to provide a lift solution. For larger projects, Dual can order bulk materials providing cost-saving and material continuity.

- Lift Car Interiors

- New and Refurbishments

- Door and Landing Frames

- New and Cladding

- Landing and Car Doors

- New and Reskins

- Fixtures (COP/LOP/LIP)

- New and Modified

- Fixture Components (Lighting/Displays/Comms/Buttons)

- Engraving and Studding Services

- Fabrication of associated items (Trims/Skirting/Guarding)

- Store Items (Fans/Signage)

- Builders Protection and Protective Blankets

- Provide Escalator and Moving Walk Items

- Glass and Steel Balustrading

- Skirting and Trim

- Provide single solution products for established lifts:

- Mirrors

- Communication Devices

- Displays + Programming

- Buttons

- Handrails

- Guarding

- Reskins/Cladding

Design Services & Bespoke Solutions

We have an experienced, multi-skilled team who can provide bespoke solutions and design services for all aspects of your lift project

Workshops

Dual’s facility in Osborne Park incorporating Wood, Metal, and Engraving workshops make this the one-stop shop for your complete lift project

Woodwork

Our woodwork area of the factory is home to the manufacturing of our high-quality interiors as well as door frames. Our extensive storage area allows us to maintain a large range of products including a variety of thicknesses of core materials such as MDFs, BS Marine plywood and other essentials, Dual ensure we meet our customer deadlines and critical project timeframes by reducing the waiting times for the majority of our products.

The centre piece of this department is the 18-metre long BIESSE ROVER AS FT, a self-loading CNC timber routing & cutting machine, which delivers a high-quality product at blistering speeds, reducing handling time and creating a safer working environment. The Biesse has the ability to calculate cutting layouts which reduces unnecessary material wastage as well as labor time, freeing our highly skilled trades people to concentrate on manufacturing and assembling our high-end products. Communication and efficiency are vital as we strive to produce our works in an injury free and safe environment.

Dual’s skilled team have experience working with veneers, laminates, glass, various metals such as stainless steel and many other products. Our wide-spread skills and knowledge are key to ensuring the customer receives a service that is beyond their expectations and in a time frame that helps projects run smoothly for our clients.

Metalwork

Our well-equipped metalwork shop allows us to produce a wide range of products such a motor room guarding, door frames and other essentials in the lift and construction industries.

Two CNC press-brakes and a CNC guillotine allow in-house manufacturing of a wide range of products and our team of skilled metalworkers are always on hand to complete even the simplest of tasks in a timeframe that suits our clients.

Dual’s metalwork team are skilled in a wide range of welding techniques including MIG & TIG welding and regularly work with materials such as stainless & mild steels and aluminium, as well as heavy duty steel.

Located in their own individual booths, our trades people ensure that they work in a safe, clean, and productive manner with health & safety a priority at Dual. Regular training & toolbox talks ensure our team are in constant communication and working to high standards to satisfy our clients’ needs and requirements.

Engraving

Our engraving department is equipped with both rotary engraved CNC and pantograph machines and with over forty years’ experience in the commercial and industrial engraving industry, our staff work to an extremely high standard and offer quality engraved products.

Materials used include 304 and 316 grade stainless steel, anodized aluminium, acrylics & two-ply plastics such as Romark.